Bicol Regional Food Innovation Center

PROF. MA. JANESA A. REYES

BRFIC Director

ANNOUNCEMENTS

The RDESys Integrated Databank System is now live! Experience the future of data management. The Call for BU-Funded Research and Development Proposals is now open until May 15, 2025 . Submit through the RDESys-ProMIS: Proposal Management Information System. Click Submit Now!

About Us

The Bicol Regional Food Innovation Center (BRFIC) shall develop and implement integrated RDE for the University, the Micro, Small, and Medium Enterprises (MSMEs), the Barangay Micro Business Enterprises (BMBEs), and the food industry in the region to transform concepts into food products and maximize the value of agricultural and fishery resources. The center shall:

- Conduct research in collaboration with faculty, students, and support staff on food innovation and the selection of appropriate packaging materials;

- Provide capacity building and technical assistance for faculty, students, MSMEs, and other stakeholders to upgrade good manufacturing operations and food processing systems, food processing standardization, and selecting packaging materials for food products;

- Establish partnerships and linkages with other Higher Education Institutions (HEIs), MSMEs, and other research institutions to develop the competencies of Bachelor of Science in Food Technology (BSFT) students, provide facilities, and implement collaborative research programs to improve local food products; and

- Review and monitor RDE undertakings under the disciplinal coverage of the Center.

Functions

The Philippine agriculture sector is made up of 4 sub-sectors: farming, fisheries, livestock, and forestry. With the latter 2 sectors being very small. The fisheries sector is divided into 3 sub-sectors: commercial, municipal, and aquaculture (cultivation of the natural produce of bodies of water).

The Bicol Region is one of the regions which play an important role in the Philippine agricultural economy. It is predominantly agricultural with close to 50% of its workforce dependent on agriculture for livelihood and survival. Data from National Economic and Development Authority (NEDA) shows that agriculture contributes 32% of the region’s economic output. It also accounts for 70% of all commodity outflows of the region. Bicol is known as a major producer of agricultural food products such as pineapple, root crops, coconut, fish from aquaculture and capture fisheries. Part of the region’s Gross Domestic Product (GDP) comes from the sale and export of these locally produced products/commodities.

A World Bank study, however, revealed that the country’s competitive edge in its key commodities has been slipping, and few new agricultural products have emerged where the country can compete effectively in the world markets. A report from the Department of Agriculture (DA) revealed that the declining competitiveness of Philippine agriculture vis-à-vis other countries in the Association of Southeast Asian Nations (ASEAN) region had been due to (a) inadequate Research and Development (R&D) on high value products and their post-harvest handling, (b) almost non-existent market information system for small farmers, (c) poorly defined and inadequately enforced quarantine, food, and biosafety standards, and (d) ad hoc and poorly maintained investments in rural infrastructure. These problems make it difficult for agricultural and fishery products to compete with cheaper and often higher quality imports or penetrate international markets.

It is these foregoing realities, and the support of stakeholders in the region, that gave rise to the establishment of the Bicol Regional Food Innovation and Commercialization Center (BRFICC) at Bicol University (BU). In 2014, the Department of Science and Technology (DOST) Regional Office No. V, BU and the Provincial Government of Albay entered into a Memorandum of Agreement (MOA) for the Establishment of BRFICC. BU to serve as the Host institution for the Center. It was on September 27, 2017, during the 119th Regular Meeting of the BU Board of Regents at the Commission on Higher Educated (CHED), Manila that the Board of Regents approved the establishment of BRFICC. In 2024, with the approval of the Research, Development, and Extension Manual (RDEM), BRFICC was renamed to Bicol Regional Food Innovation Center (BRFIC).

The establishment of Food Innovation Center in every region as part of the DOST’s National Innovation Strategy “Filipinovation”, intends to enhance the innovative capacities of Micro, Small and Medium Enterprise (MSMEs) and Barangay Micro Business Enterprises (BMBEs) in the food Industry to improve the quality of their existing products and/or develop new ones thereby increasing their competitiveness in local and export markets.

The Center, serves as an area to create and test new products. It also links the MSMEs and BMBEs with the array of services and resources for them to be more efficient, more competitive and consequently more profitable. The center’s focus is on the region’s ethnic or indigenous food products, nutrition-enhancing food, disaster-ready food, and gender- and/or age-responsive food products.

The facilities and services offered in the center provide faculty and student researchers the technology needed to come up with food products that will be able to address the mind to market concept of food product development. The center also provides the BS Food Technology students the technologies that will help them apply innovative food preservation methods and techniques to make quality and safe food products.

Vision and Mission

Vision Statement

A center of standards and excellence on food science technology and innovation, recognized for world-class products and services.

Mission Statement

To serve as an integrated innovation and support service network for the development and commercialization of processed foods to:

- Maximize value addition to diverse food resources; and

- Contribute to the sustainable development of the Philippine food industry.

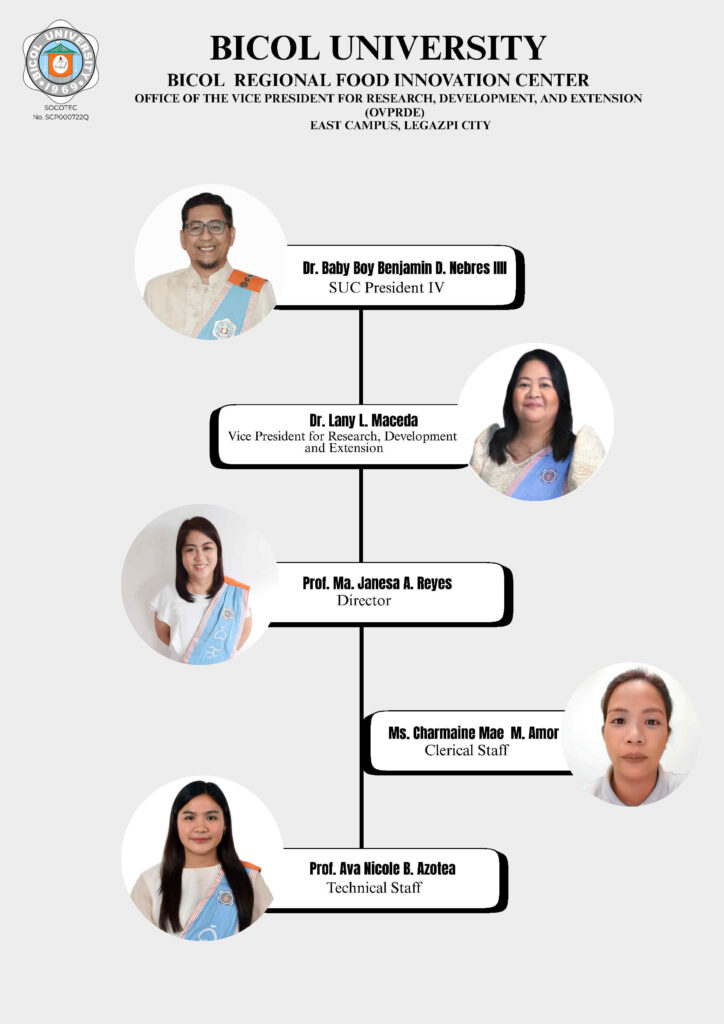

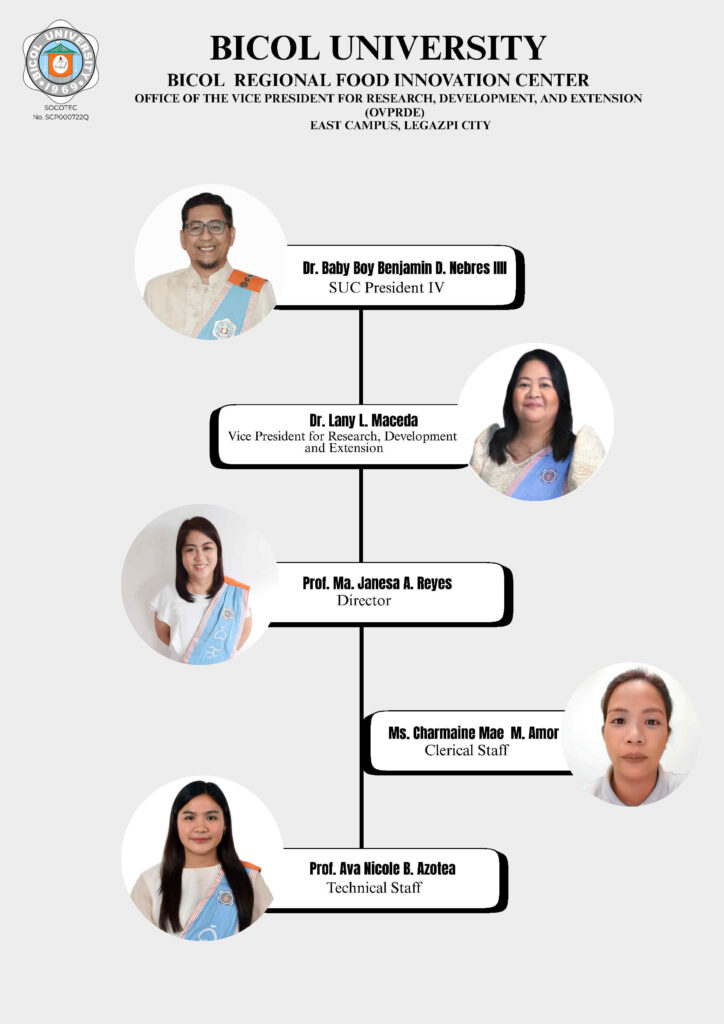

Organizational Chart

Programs and Projects

Development and Characterization of Energy Bar Utilizing Sweet Potato, Coco Yam and Rice Germ (2019-2020)

This study developed and characterized an energy bar from sweet potato and coco yam. It determined the most preferred formulation, sensory characteristics and acceptability, nutritional value and microbiological load. Cabinet drying was used for sweet potato, coco yam and rice germ. Three samples were made with varying proportions of sweet potato, coco yam and rice germ while the other ingredients remained constant. Three samples were subjected to sensory evaluation to determine most preferred sample, acceptability and sensory attributes. The nutritional composition and microbial load of the most preferred sample was analyzed.

Characterization and Process Optimization of White Oyster Mushroom (Pleurotus ostreatus) (2019-2021)

Study 1: Characterization of Fresh and Vacuum-Fried White Oyster Mushroom (Pleurotus ostreatus)

This study focused on the characterization of fresh and vacuum-fried white oyster mushroom. Fresh oyster mushroom was characterized through determination of proximate composition (Moisture, Ash, Protein, Fat and Carbohydrates) and physico-chemical properties (pH and Aw). The vacuum-fried white oyster mushroom was characterized in terms of proximate composition (Moisture, Ash, Protein, Fat and Carbohydrates), physico-chemical properties (pH and Aw), nutritional composition (Ca, Fe, Na, K and Zn), microbiological properties (Aerobic Plate Count and Yeast and Mold Count) and product profile in terms of sensory characteristics and acceptability.

Study 2: Development of Optimum Processing Conditions of Vacuum-Fried White Oyster Mushroom (Pleurotus ostreatus)

Fresh white oyster mushrooms were subjected to various pretreatments before undergoing vacuum frying. The process was optimized by modifying key parameters such as temperature and frying time. The vacuum-fried products were then evaluated for moisture content, fat content, and sensory acceptability to determine the optimal formulation. The study aimed to develop a high-quality, healthier fried snack with improved color, texture, and flavor, while retaining nutritional value.

Pinangat Making in Camalig Albay: Documentation of an Intangible Cultural Heritage (2022-2024)

Study 1: History and Lore of Pinangat Production in Camalig, Albay

Study 2: Documentation of Pinangat Production in Camalig, Albay

The project included two studies dedicated to preserving the intangible cultural heritage of pinangat making in Camalig, Albay. Study 1 explored the history and cultural stories behind pinangat production, and Study 2 documented the production process. The goal of both studies was to ensure that this traditional craft is preserved.

Utilization of Pili Nut (Canarium ovatum, Engl.) (2023-2024)

Study 1: Product Development of Pili nut to Plant-based Mayonnaise

This study focused on developing a plant-based mayonnaise utilizing pili milk added to soybean oil. The main objective of the study was to develop a plant-based mayonnaise utilizing Pili (Canarium ovatum), specifically it sought to: develop the process of making pili mayonnaise; evaluate the organoleptic properties and acceptability; determine the standard formulation, nutritional value and physico-chemical properties of pili mayonnaise.

Quality and Safety Management of Dehydrated Pili (Canarium ovatum) Kernel (2024-2025)

Study 1: Profiling and Process Documentation of Producing Dehydrated Pili (Canarium ovatum, Engl.) Nut in the Bicol Region

The study conducted a survey on the dehydrated pili nut processors in the Bicol Region. It evaluated the food safety compliance of the production process of dehydrated pili nut. A Hazard Analysis and Critical Control Point (HACCP) Plan for dehydrated pili nut processing will be formulated.

Study 4: Standardization and Optimization of the Dehydration Process of the Pili Nuts

This study aims to identify the ideal conditions for dehydrating pili nuts. Specifically, it seeks to establish the most favorable temperature range for dehydration, determine the appropriate drying duration at each temperature, and define the optimum overall conditions to produce high-quality dehydrated pili nuts.

Determination of the Physico-chemical Characteristics, Microbiological Load, Nutritional Content and Shelf Life of Sweet Potato Coco Yam Energy Bar (2025)

The study will determine the shelf life of the energy bar by conducting Physico-chemical analysis to determine the moisture content, and water activity; texture analysis; microbiological analysis to determine the Total Plate Count, Yeast and Mold Count, Salmonella and E. coli. Sensory evaluation will also be conducted to evaluate the acceptability of the energy bar for designated period of analysis. The nutritional content of the energy bar will be determined through nutritional fact analysis.

Resources

Construction of BRFIC building was completed in year 2017. The building houses the following facilities:

- Amphitheater

The amphitheater can accommodate 200 people. It is airconditioned, with folding chairs and equipped with sound system. It is suitable for meetings, seminars, trainings, and conferences. - Training Hall

The training hall can accommodate 100 people. It is air-conditioned and has long table and chairs. It is suitable for meetings, seminars, and trainings. - Lecture Room

The lecture can accommodate 75 people. It is suitable for meetings, seminars, and trainings. - Kitchen

The kitchen is the area where raw materials are stored, prepared, and cooked prior to processing or sensory evaluation. It is adjacent to sensory evaluation room to provides ease in the serving of samples prior to evaluation. - Sensory Evaluation Room

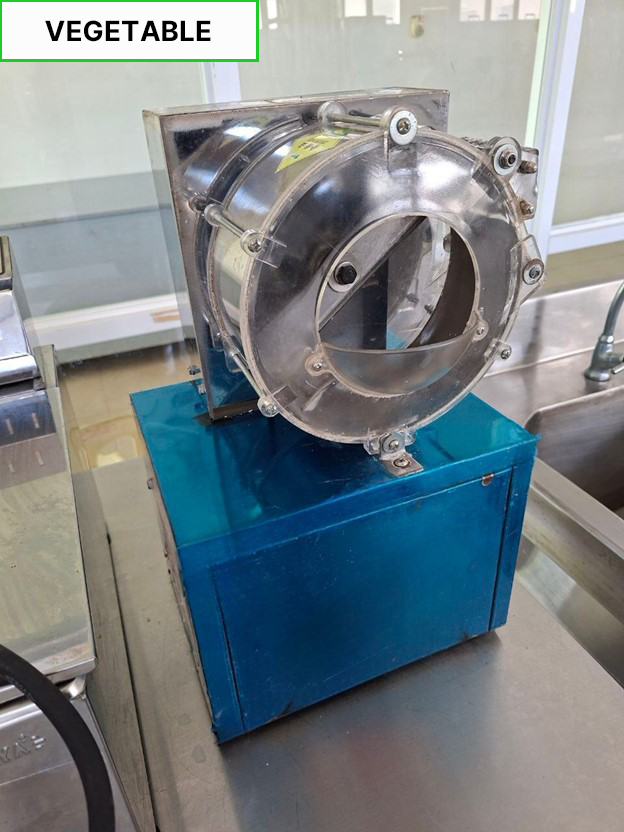

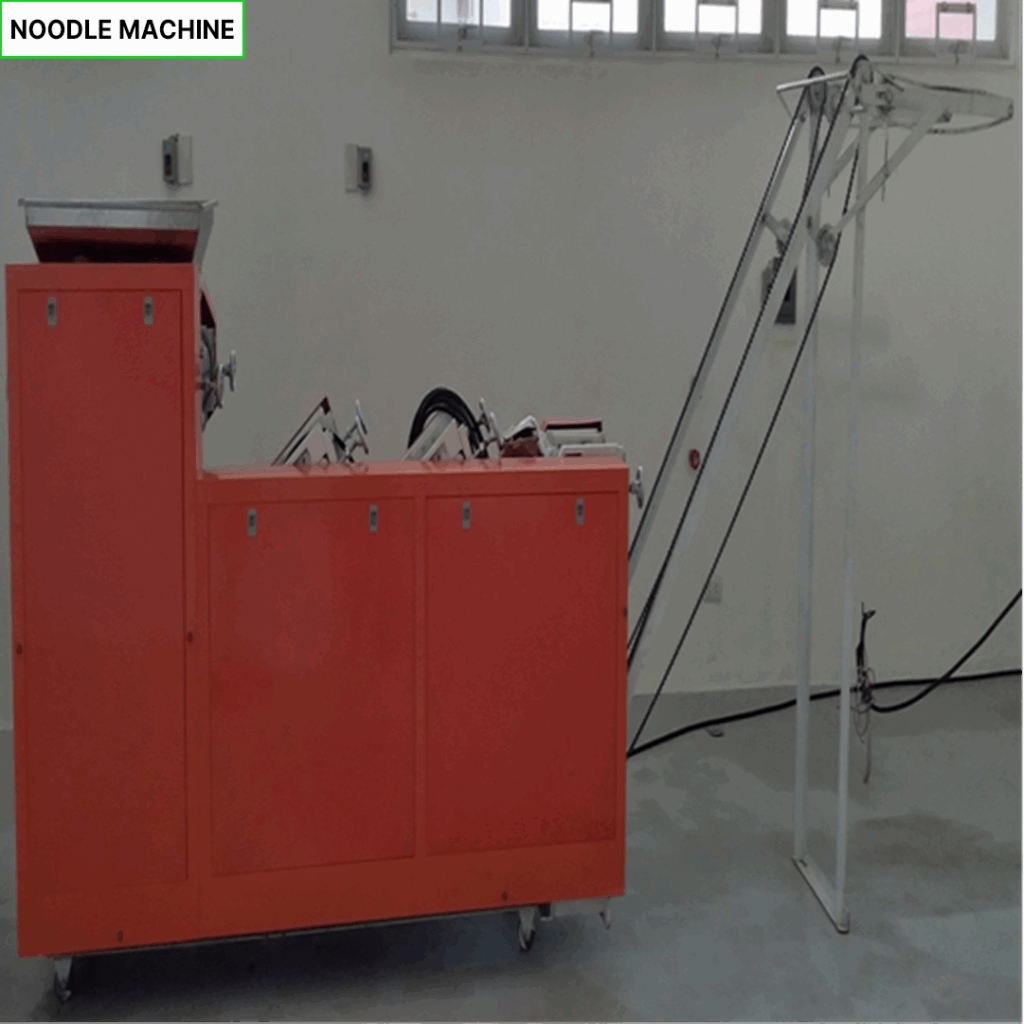

The center has a sensory evaluation room with 4 panel booths. These panel booths provide independence to panelists during food evaluation. Each panel booth is equipped with lights to mask color difference of food samples. - Production Area

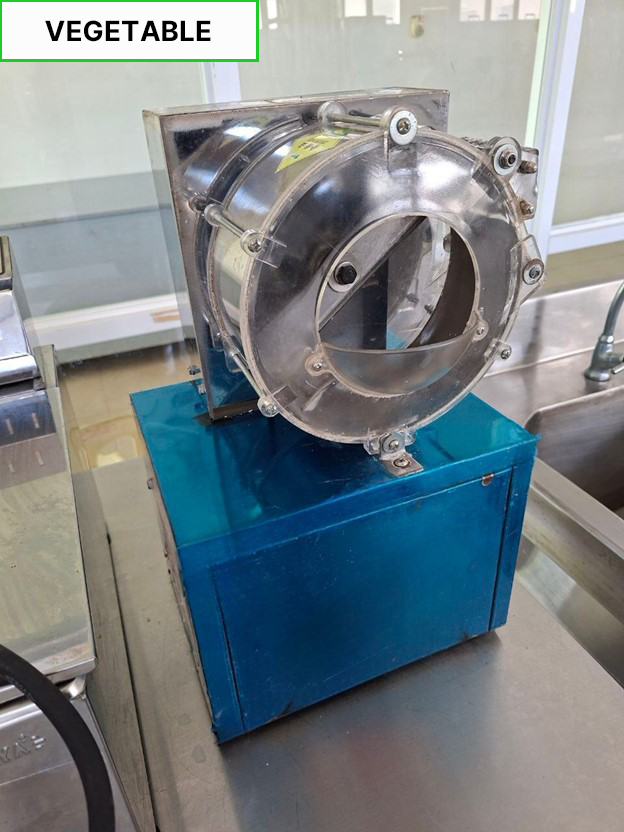

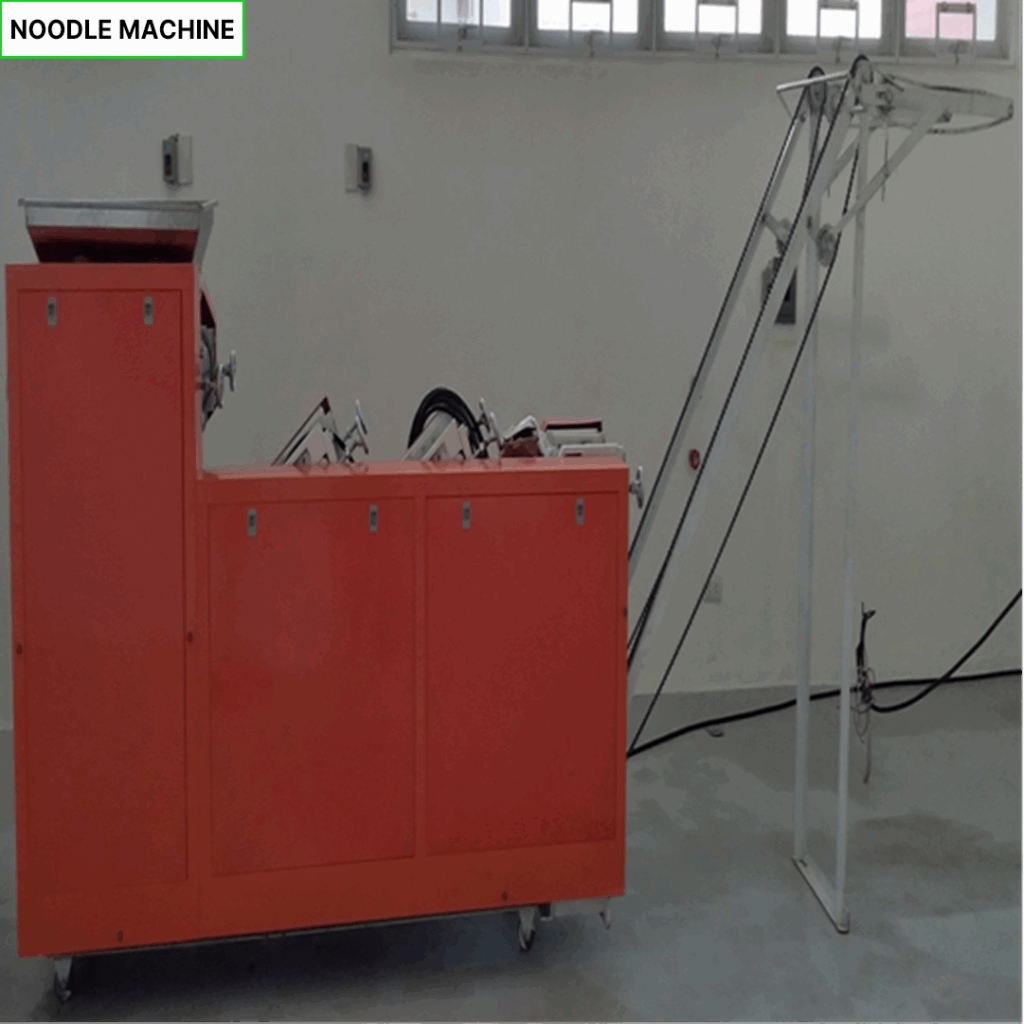

The production area houses BRFIC’s food processing and packaging equipment. This is an area where food pre-processing, processing, and packaging are carried out.

Resources

Reports

*Insert Text*

Contact Us

BRFIC Building East Campus, Legazpi City, Albay

bu-brficc@bicol-u.edu.ph

Bicol Regional Food Innovation and Commercialization Center

Office Hours:

Monday – Friday: 8:00 a.m. – 5:00 p.m.

Saturday – Sunday: Closed

About Us

The Bicol Regional Food Innovation Center (BRFIC) shall develop and implement integrated RDE for the University, the Micro, Small, and Medium Enterprises (MSMEs), the Barangay Micro Business Enterprises (BMBEs), and the food industry in the region to transform concepts into food products and maximize the value of agricultural and fishery resources. The center shall:

- Conduct research in collaboration with faculty, students, and support staff on food innovation and the selection of appropriate packaging materials;

- Provide capacity building and technical assistance for faculty, students, MSMEs, and other stakeholders to upgrade good manufacturing operations and food processing systems, food processing standardization, and selecting packaging materials for food products;

- Establish partnerships and linkages with other Higher Education Institutions (HEIs), MSMEs, and other research institutions to develop the competencies of Bachelor of Science in Food Technology (BSFT) students, provide facilities, and implement collaborative research programs to improve local food products; and

- Review and monitor RDE undertakings under the disciplinal coverage of the Center.

Functions

The Philippine agriculture sector is made up of 4 sub-sectors: farming, fisheries, livestock, and forestry. With the latter 2 sectors being very small. The fisheries sector is divided into 3 sub-sectors: commercial, municipal, and aquaculture (cultivation of the natural produce of bodies of water).

The Bicol Region is one of the regions which play an important role in the Philippine agricultural economy. It is predominantly agricultural with close to 50% of its workforce dependent on agriculture for livelihood and survival. Data from National Economic and Development Authority (NEDA) shows that agriculture contributes 32% of the region’s economic output. It also accounts for 70% of all commodity outflows of the region. Bicol is known as a major producer of agricultural food products such as pineapple, root crops, coconut, fish from aquaculture and capture fisheries. Part of the region’s Gross Domestic Product (GDP) comes from the sale and export of these locally produced products/commodities.

A World Bank study, however, revealed that the country’s competitive edge in its key commodities has been slipping, and few new agricultural products have emerged where the country can compete effectively in the world markets. A report from the Department of Agriculture (DA) revealed that the declining competitiveness of Philippine agriculture vis-à-vis other countries in the Association of Southeast Asian Nations (ASEAN) region had been due to (a) inadequate Research and Development (R&D) on high value products and their post-harvest handling, (b) almost non-existent market information system for small farmers, (c) poorly defined and inadequately enforced quarantine, food, and biosafety standards, and (d) ad hoc and poorly maintained investments in rural infrastructure. These problems make it difficult for agricultural and fishery products to compete with cheaper and often higher quality imports or penetrate international markets.

It is these foregoing realities, and the support of stakeholders in the region, that gave rise to the establishment of the Bicol Regional Food Innovation and Commercialization Center (BRFICC) at Bicol University (BU). In 2014, the Department of Science and Technology (DOST) Regional Office No. V, BU and the Provincial Government of Albay entered into a Memorandum of Agreement (MOA) for the Establishment of BRFICC. BU to serve as the Host institution for the Center. It was on September 27, 2017, during the 119th Regular Meeting of the BU Board of Regents at the Commission on Higher Educated (CHED), Manila that the Board of Regents approved the establishment of BRFICC. In 2024, with the approval of the Research, Development, and Extension Manual (RDEM), BRFICC was renamed to Bicol Regional Food Innovation Center (BRFIC).

The establishment of Food Innovation Center in every region as part of the DOST’s National Innovation Strategy “Filipinovation”, intends to enhance the innovative capacities of Micro, Small and Medium Enterprise (MSMEs) and Barangay Micro Business Enterprises (BMBEs) in the food Industry to improve the quality of their existing products and/or develop new ones thereby increasing their competitiveness in local and export markets.

The Center, serves as an area to create and test new products. It also links the MSMEs and BMBEs with the array of services and resources for them to be more efficient, more competitive and consequently more profitable. The center’s focus is on the region’s ethnic or indigenous food products, nutrition-enhancing food, disaster-ready food, and gender- and/or age-responsive food products.

The facilities and services offered in the center provide faculty and student researchers the technology needed to come up with food products that will be able to address the mind to market concept of food product development. The center also provides the BS Food Technology students the technologies that will help them apply innovative food preservation methods and techniques to make quality and safe food products.

Vision and Mission

Vision Statement

A center of standards and excellence on food science technology and innovation, recognized for world-class products and services.

Mission Statement

To serve as an integrated innovation and support service network for the development and commercialization of processed foods to:

- Maximize value addition to diverse food resources; and

- Contribute to the sustainable development of the Philippine food industry.

Organizational Chart

Programs and Projects

Development and Characterization of Energy Bar Utilizing Sweet Potato, Coco Yam and Rice Germ (2019-2020)

This study developed and characterized an energy bar from sweet potato and coco yam. It determined the most preferred formulation, sensory characteristics and acceptability, nutritional value and microbiological load. Cabinet drying was used for sweet potato, coco yam and rice germ. Three samples were made with varying proportions of sweet potato, coco yam and rice germ while the other ingredients remained constant. Three samples were subjected to sensory evaluation to determine most preferred sample, acceptability and sensory attributes. The nutritional composition and microbial load of the most preferred sample was analyzed.

Characterization and Process Optimization of White Oyster Mushroom (Pleurotus ostreatus) (2019-2021)

Study 1: Characterization of Fresh and Vacuum-Fried White Oyster Mushroom (Pleurotus ostreatus)

This study focused on the characterization of fresh and vacuum-fried white oyster mushroom. Fresh oyster mushroom was characterized through determination of proximate composition (Moisture, Ash, Protein, Fat and Carbohydrates) and physico-chemical properties (pH and Aw). The vacuum-fried white oyster mushroom was characterized in terms of proximate composition (Moisture, Ash, Protein, Fat and Carbohydrates), physico-chemical properties (pH and Aw), nutritional composition (Ca, Fe, Na, K and Zn), microbiological properties (Aerobic Plate Count and Yeast and Mold Count) and product profile in terms of sensory characteristics and acceptability.

Study 2: Development of Optimum Processing Conditions of Vacuum-Fried White Oyster Mushroom (Pleurotus ostreatus)

Fresh white oyster mushrooms were subjected to various pretreatments before undergoing vacuum frying. The process was optimized by modifying key parameters such as temperature and frying time. The vacuum-fried products were then evaluated for moisture content, fat content, and sensory acceptability to determine the optimal formulation. The study aimed to develop a high-quality, healthier fried snack with improved color, texture, and flavor, while retaining nutritional value.

Pinangat Making in Camalig Albay: Documentation of an Intangible Cultural Heritage (2022-2024)

Study 1: History and Lore of Pinangat Production in Camalig, Albay

Study 2: Documentation of Pinangat Production in Camalig, Albay

The project included two studies dedicated to preserving the intangible cultural heritage of pinangat making in Camalig, Albay. Study 1 explored the history and cultural stories behind pinangat production, and Study 2 documented the production process. The goal of both studies was to ensure that this traditional craft is preserved.

Utilization of Pili Nut (Canarium ovatum, Engl.) (2023-2024)

Study 1: Product Development of Pili nut to Plant-based Mayonnaise

This study focused on developing a plant-based mayonnaise utilizing pili milk added to soybean oil. The main objective of the study was to develop a plant-based mayonnaise utilizing Pili (Canarium ovatum), specifically it sought to: develop the process of making pili mayonnaise; evaluate the organoleptic properties and acceptability; determine the standard formulation, nutritional value and physico-chemical properties of pili mayonnaise.

Quality and Safety Management of Dehydrated Pili (Canarium ovatum) Kernel (2024-2025)

Study 1: Profiling and Process Documentation of Producing Dehydrated Pili (Canarium ovatum, Engl.) Nut in the Bicol Region

The study conducted a survey on the dehydrated pili nut processors in the Bicol Region. It evaluated the food safety compliance of the production process of dehydrated pili nut. A Hazard Analysis and Critical Control Point (HACCP) Plan for dehydrated pili nut processing will be formulated.

Study 4: Standardization and Optimization of the Dehydration Process of the Pili Nuts

This study aims to identify the ideal conditions for dehydrating pili nuts. Specifically, it seeks to establish the most favorable temperature range for dehydration, determine the appropriate drying duration at each temperature, and define the optimum overall conditions to produce high-quality dehydrated pili nuts.

Determination of the Physico-chemical Characteristics, Microbiological Load, Nutritional Content and Shelf Life of Sweet Potato Coco Yam Energy Bar (2025)

The study will determine the shelf life of the energy bar by conducting Physico-chemical analysis to determine the moisture content, and water activity; texture analysis; microbiological analysis to determine the Total Plate Count, Yeast and Mold Count, Salmonella and E. coli. Sensory evaluation will also be conducted to evaluate the acceptability of the energy bar for designated period of analysis. The nutritional content of the energy bar will be determined through nutritional fact analysis.

Resources

Construction of BRFIC building was completed in year 2017. The building houses the following facilities:

- Amphitheater

The amphitheater can accommodate 200 people. It is airconditioned, with folding chairs and equipped with sound system. It is suitable for meetings, seminars, trainings, and conferences. - Training Hall

The training hall can accommodate 100 people. It is air-conditioned and has long table and chairs. It is suitable for meetings, seminars, and trainings. - Lecture Room

The lecture can accommodate 75 people. It is suitable for meetings, seminars, and trainings. - Kitchen

The kitchen is the area where raw materials are stored, prepared, and cooked prior to processing or sensory evaluation. It is adjacent to sensory evaluation room to provides ease in the serving of samples prior to evaluation. - Sensory Evaluation Room

The center has a sensory evaluation room with 4 panel booths. These panel booths provide independence to panelists during food evaluation. Each panel booth is equipped with lights to mask color difference of food samples. - Production Area

The production area houses BRFIC’s food processing and packaging equipment. This is an area where food pre-processing, processing, and packaging are carried out.

Resources

Reports

*Insert Text*

Contact Us

BRFIC Building East Campus, Legazpi City, Albay

bu-brficc@bicol-u.edu.ph

Bicol Regional Food Innovation and Commercialization Center

Office Hours:

Monday – Friday: 8:00 a.m. – 5:00 p.m.

Saturday – Sunday: Closed